- Introduction to Veg cutting machine

- Understanding Your Vegetable Cutting Needs

- Types of Veg Cutting Machines

- Selecting the Right Vegetable Cutting Machine

- How to do Installation and Setup

- Using the Vegetable Cutting Machine

- Maintenance and Cleaning

- Safety and Compliance

- Upgrading and Replacing Vegetable Cutting Machines

- Conclusion

Introduction to Veg cutting machine

A veg cutting machine is an essential piece of equipment in any commercial kitchen, helping to save time and ensure uniform cuts for a variety of vegetables.

This guide will help you understand the different types of vegetable cutting machines, how to select the right one for your needs, and how to maintain and operate it safely and efficiently.

Understanding Your Vegetable Cutting Needs

Before purchasing a veg cutting machine, it’s important to assess your specific requirements:

- Volume: Estimate the amount of vegetables you need to process daily.

- Types of Cuts: Determine the types of cuts (slices, dices, juliennes) you need.

- Types of Vegetables: Consider the variety of vegetables you’ll be processing.

- Space: Evaluate the available space in your kitchen for the machine.

- Budget: Plan your budget for purchasing and maintaining the machine.

Types of Veg Cutting Machines

Manual Veg Cutters

- Use: Ideal for small-scale operations or when electricity is not available.

- Features: Simple hand-operated mechanisms, often with interchangeable blades.

- Advantages: Cost-effective, no electricity required, easy to use.

Electric Veg Cutters

- Use: Suitable for medium to large-scale operations.

- Features: Powered by electricity, come with multiple blades and settings.

- Advantages: Faster and more efficient than manual cutters, can handle larger volumes.

Commercial Vegetable Cutters

- Use: Designed for high-volume, commercial kitchens.

- Features: Robust construction, powerful motors, multiple attachments for different cuts.

- Advantages: Extremely efficient, durable, designed for continuous use.

Selecting the Right Vegetable Cutting Machine

Assessing Your Needs

- Volume of Processing: Choose a machine that can handle your daily vegetable processing volume.

- Types of Cuts Needed: Ensure the machine offers the cutting styles you require.

- Space and Mobility: Consider the size of the machine and whether it needs to be portable.

Key Features to Consider

- Blade Quality: Look for high-quality, stainless steel blades that stay sharp and are resistant to corrosion.

- Ease of Cleaning: Select machines with easily removable parts for thorough cleaning.

- Safety Features: Ensure the machine has safety features such as guards and emergency stop buttons.

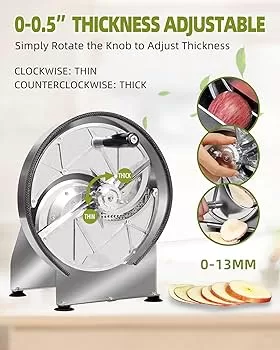

- Power and Speed Settings: For electric machines, consider models with adjustable power and speed settings for different vegetables.

How to do Installation and Setup

Professional Installation

- Hire Experts: For commercial-grade machines, professional installation is recommended to ensure proper setup and safety compliance.

- Follow Manufacturer’s Instructions: Adhere strictly to the installation guidelines provided by the manufacturer.

Optimal Placement

- Workflow Efficiency: Place the machine where it can be easily accessed and integrated into the kitchen workflow.

- Safety: Ensure the machine is placed on a stable surface and is away from high-traffic areas to prevent accidents.

Initial Setup

- Assemble the Machine: Follow the manufacturer’s instructions to assemble the machine correctly.

- Test Run: Perform a test run to ensure all parts are functioning properly.

Using the Vegetable Cutting Machine

Preparing Vegetables

- Wash and Peel: Ensure all vegetables are washed and peeled as necessary before cutting.

- Size Preparation: Cut vegetables into sizes that fit easily into the machine’s feed chute.

Operating the Machine

- Read the Manual: Familiarize yourself with the operating manual.

- Load Vegetables: Load the prepared vegetables into the feed chute.

- Select Settings: Choose the appropriate blade and settings for the desired cut.

- Start the Machine: Turn on the veg cutting machine and feed the vegetables through.

Safety Precautions

- Use Guards: Always use provided guards and handles to push vegetables through.

- Avoid Overloading: Do not overload the machine, as this can cause jams and reduce efficiency.

- Turn Off When Not in Use: Always turn off and unplug the machine when not in use.

Maintenance and Cleaning

Daily Cleaning

- Disassemble Parts: Remove all detachable parts.

- Wash Thoroughly: Wash blades and other parts with warm, soapy water.

- Sanitize: Use food-safe sanitizers to ensure hygiene.

Regular Maintenance

- Inspect Blades: Regularly check blades for sharpness and replace them as needed.

- Lubricate Moving Parts: Apply food-safe lubricant to moving parts to ensure smooth operation.

- Check Electrical Components: For electric veg cutting machine regularly inspect the power cord and plug for any damage.

Troubleshooting Common Issues

- Machine Not Turning On: Check the power supply and ensure all safety features are engaged.

- Uneven Cuts: Ensure the blades are sharp and properly aligned.

- Vegetable Jams: Clear the feed chute and avoid overloading the machine.

Safety and Compliance

Food Safety Standards

- Temperature Control: Keep processed vegetables at safe temperatures to prevent bacterial growth.

- Hygiene Practices: Maintain strict hygiene practices for all staff handling the machine.

Electrical and Mechanical Safety

- Regular Inspections: Conduct regular safety inspections to ensure all components are in good working condition.

- Safety Training: Train staff on proper operation and emergency procedures.

Upgrading and Replacing Vegetable Cutting Machines

Assess Needs

- Evaluate Performance: Regularly assess the performance of your current machine.

- Plan Upgrades: Schedule upgrades during off-peak times to minimize disruption.

Budgeting

- Allocate Funds: Set aside funds for potential upgrades and replacements.

- Seek Financing: Explore financing options if necessary.

Disposal of Old Equipment

- Eco-Friendly Disposal: Dispose of old equipment in an environmentally friendly manner.

- Donate or Sell: Consider donating or selling equipment that is still functional.

Conclusion

A veg cutting machine can significantly enhance the efficiency and consistency of your kitchen operations. By understanding your needs, selecting the right machine, ensuring proper installation and maintenance, and adhering to safety protocols, you can optimize your veg cutting machine and improve overall kitchen productivity.

Regular monitoring and timely upgrades will ensure your equipment remains in top condition, meeting the high standards required in the food service industry.

About Author nikita kapali

You May Also Like…

2024 Buyer’s Guide: How to Choose the Best Auto Clean Chimney for Your Kitchen

IntroductionA chimney is essential for a clean and safe kitchen. Kitchen chimneys are essential for aesthetics and...

How to Choose the Right POS Software for Your Restaurant in India

Introduction Profits are what make it all worthwhile. Running a successful restaurant requires an efficient...