- Introduction To The Commercial Kitchen Equipment Manufacturers:

- Step 1: Identifying Leading Commercial kitchen equipment Manufacturers

- Step 2: Understanding Manufacturer Offerings

- Step 3: Evaluating Manufacturer Reputation

- Step 4: Selecting the Right Equipment

- Step 5: Installation and Integration

- Step 6: Maintenance and Support

- Conclusion

Introduction To The Commercial Kitchen Equipment Manufacturers:

Commercial kitchen equipment manufacturers ensures reliability, efficiency, and durability of the equipment. This guide will provide detailed steps on identifying and selecting top commercial kitchen equipment manufacturers, understanding their offerings, and integrating these products into your kitchen operations.

Step 1: Identifying Leading Commercial kitchen equipment Manufacturers

The first step is to identify the top manufacturers known for their quality and reliability. Here are some methods to find them:

-

Industry Reviews and Ratings:

- Check industry publications and online review sites for ratings and reviews of different manufacturers.

- Look for awards and recognitions given to manufacturers by reputable industry bodies.

-

Trade Shows and Expos:

- Attend industry trade shows and expos to see the latest products from various manufacturers and speak directly with their representatives.

-

Professional Associations:

- Utilize resources from professional associations like the National Restaurant Association (NRA) or the North American Association of Food Equipment Manufacturers (NAFEM) to get recommendations.

-

Peer Recommendations:

- Seek recommendations from industry peers and colleagues who have firsthand experience with different manufacturers.

Step 2: Understanding Manufacturer Offerings

Once you’ve identified potential manufacturers, delve into their product offerings to ensure they meet your specific needs.

-

Product Range:

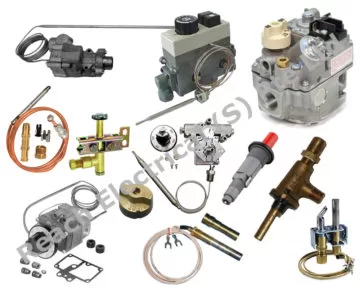

- Evaluate the range of products offered. Top manufacturers typically offer a comprehensive selection of equipment, including ovens, refrigerators, dishwashers, and more.

-

Quality and Durability:

- Assess the quality and durability of their products. Look for materials used, build quality, and longevity.

-

Innovation and Technology:

- Check for innovation in their product lines. Manufacturers that incorporate the latest technology and innovative features can provide efficiency and convenience.

-

Customization Options:

- Some manufacturers offer customization options to tailor equipment to your specific needs. This can be particularly useful for unique kitchen layouts or specialized operations.

Step 3: Evaluating Manufacturer Reputation

Manufacturer reputation is critical to ensure reliable products and services.

-

Customer Testimonials and Case Studies:

- Look for customer testimonials and case studies on the manufacturer’s website or request them from their sales representatives.

-

Service and Support:

- Assess the level of after-sales service and support offered by the manufacturer. This includes warranty, maintenance services, and availability of spare parts.

-

Sustainability Practices:

- Consider manufacturers with strong sustainability practices, such as energy-efficient products and environmentally friendly manufacturing processes.

Step 4: Selecting the Right Equipment

Choosing the right equipment involves detailed consideration of your kitchen’s specific needs.

-

Kitchen Layout and Space:

- Measure your kitchen space and ensure the equipment fits well without causing congestion.

-

Operational Needs:

- Match the equipment capabilities with your operational needs. For instance, high-volume restaurants might need heavy-duty equipment, while smaller cafes might focus on multifunctional appliances.

-

Budget:

- Balance quality and cost. While top-tier manufacturers might offer the best products, ensure they fit within your budget constraints.

-

Compliance and Certification:

- Ensure the equipment complies with local health and safety regulations and has necessary certifications.

Step 5: Installation and Integration

Proper installation and integration of equipment are crucial for optimal performance.

- Professional Installation:

- Hire professional installers certified by the manufacturer to ensure proper setup and to avoid voiding warranties.

- Training:

- Ensure staff receives adequate training on using the new equipment efficiently and safely.

- Integration with Existing Systems:

- Ensure the new equipment integrates well with existing systems and workflows in your kitchen.

Step 6: Maintenance and Support

-

Ongoing maintenance and support are essential for the longevity and efficiency of your equipment.

-

Regular Maintenance Schedule:

- Set up a regular maintenance schedule as recommended by the manufacturer. This includes cleaning, inspections, and servicing.

-

Manufacturer Support:

- Utilize the manufacturer’s support services for troubleshooting and repairs. Maintain records of service history for reference.

-

Spare Parts and Accessories:

- Keep an inventory of essential spare parts and accessories to minimize downtime in case of equipment failure.

-

Conclusion

Choosing the right commercial kitchen equipment manufacturers can significantly impact the efficiency and success of your kitchen operations. By carefully evaluating manufacturers based on their reputation, product offerings, and support services, and by selecting and maintaining equipment properly, you can ensure a well-equipped, reliable, and efficient kitchen.

About Author nikita kapali

You May Also Like…

Professional Hospitality Setup and Placement Consultancy in Bangalore

IntroductionBangalore has been recognized as one of India's fastest growing market for hospitality. With the growing...

Expert Chef-Led Consulting for Asian Food Café Restaurants

IntroductionAsian food establishments have emerged as one of the fastest-growing categories in the world of...